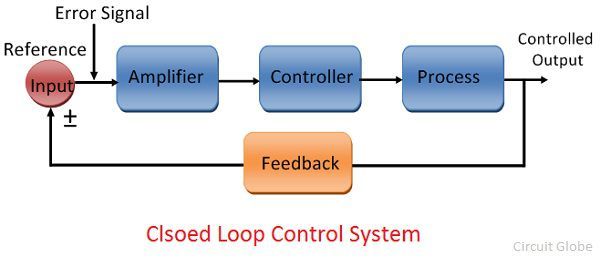

The digital pressure regulators are closed-loop structures and you can control them from a remote signal. A remote pressure sensor is placed in the electronic pressure regulator valve to draw feedback signals from the piping system. The closed-loop system eliminates the pressure drop effects from any point of the piping system.

The closed loop of the pressure valves improves the responsiveness of the system. The closed-loop system assists to maintain the pressure within the pressure valves within a certain range. It is the effectiveness of the closed loop circuit that high-tech industries do prefer over the open circuit.

Why use the closed-loop circuit?

The closed-loop circuit has major benefits over the open-loop circuits and also to the manual control system.

Better production:

The closed-loop circuit of the electronic air pressure regulator ensures the efficiency and production of the processes. When you are using the closed circuit, it ensures you are going to produce a large production quantity. This can be a difference in earning more revenues.

The control of the system:

When you have installed the closed loop, you can alter the temperature, pressure, and ratio of the chemical in a chemical reaction at any time. You can never able to produce a product according to the formula, without maintaining the precise temperature, pressure, and ratio of the chemicals. The digital pressure regulator with a closed loop circuit enables us to maintain the required level of these variables.

Consistent Quality:

The electronic air regulator with the closed loop system would ensure the precise quality of the product. This enables you to implement standardization in the production system. It can be impossible to regulate the consistent level of production by the mechanical valves. You can set certain variables to ensure a consistent quality of the products. In the Chemical and Pharmaceutical industry, it is quite necessary to maintain the precise temperature and pressure of the reaction

The responsiveness of the system:

You can spot the tiniest of fluctuations in the flow of the liquid. The whole closed-loop system is a sensitive network of valves and all the valves regulate the pressure at the desired level.

The control of the system can be more responsive and this is the main reason digital pressure regulators are preferred over mechanical valves in the high-tech industry. The remote control system of the closed-loop circuit is more responsive than the mechanical valves.

Centralized system:

There can be many switches in a piping system, it can be difficult to remember the whole circuit of the switches. But the closed-loop circuits are centrally connected to the main computer. You can configure the whole system by sitting on your computer screen. The centralized connected system is the basic requirement of today’s modern reaction chambers.

Conclusion:

The closed-loop circuit is the state technology used in the high-technology industry. You can increase and maintain the consistent quality of the products by the closed loop structure. You only have to set instructions and parameters for the commencement of a reaction. You can ensure more control over the system by installing closed-loop circuits.